Waste heat is the biggest source of energy on the planet. A newly developed waste heat engine could recycle all that lost heat back into the energy, reducing our use of fossil fuels

By Brian Blum, Israel21c

According to a study from Yale University’s School of the Environment, some 70 percent of all energy produced by humanity is squandered as “waste heat,” much of it a byproduct of running large industrial plants.

Waste heat “is the biggest source of energy on the planet,” says Joseph King, one of the program directors for the US government’s Advanced Research Projects Agency Energy.

Israeli startup Luminescent has developed a technology to capture this waste heat – which is full of climate change-exacerbating CO2 – and turn it into electricity, either to power the facility itself at a lower cost or to be sold back to the electrical grid.

Capturing wasted heat is a known need; Facebook announced a plan in 2020 to channel the waste heat from its center in Odense, Denmark, to warm nearly 7,000 homes, and another Danish endeavor uses heat from a crematorium to heat local homes.

But mainly, the business of heat capture focuses on large facilities with substantial generators, where producing and storing zero-emission electricity is more cost effective.

Luminescent is the first to address the small power generators that comprise most of the market. Its super-efficient waste heat engine will be available by mid-2023 as a pilot, with sales starting in 2025.

Although waste heat released into the air doesn’t have much direct effect on climate change, every bit of waste heat recycled into energy reduces our use of fossil fuels.

One study in the UK found that if some of the country’s biggest power stations were to divert waste heat to warming homes and offices, it could prevent the release of some 10 million tons of CO2 emissions annually.

Kinetic energy

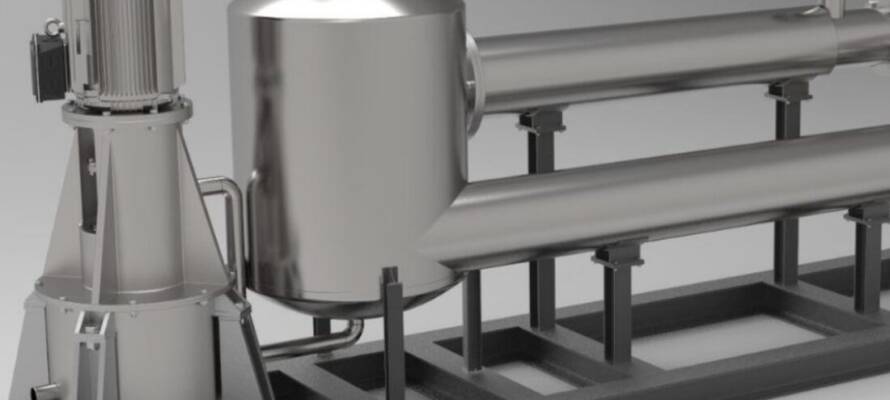

Luminescent’s unique waste heat engine uses a heat-transfer liquid (HTL), which flows in a nozzle where it’s mixed with pressurized air or other gas bubbles.

The liquid has a thousand times more thermal energy density than any gas for a similar volume.

The bubbles expand isothermally (without any change in temperature), thereby accelerating the HTL and converting it into kinetic energy. The kinetic energy operates a generator on top of the engine shaft.

The bottom line: Luminescent says its isothermal process reduces the size and doubles the efficiency of an engine compared to other operations, while providing up to 70% more power than existing setups.

The Luminescent system can store the resulting energy for up to 20 hours.

Having recently raised a $7 million seed funding round led by Grove Ventures, the company is targeting industrial operations in the United States, Europe, Japan, China and South Korea.

The Tel Aviv-based company was cofounded by Doron Tamir, a former executive at the solar energy firm Solex Renewable, and Prof. Carmel Rotschild of the mechanical engineering department at the Technion, who invented the isothermal process used by Luminescent.

Tamir tells ISRAEL21c that after a decade in the solar industry, “I came to the conclusion that solar energy with batteries is important, but if you want to be serious about energy transition, it’s part of the solution but not the solution.”

Since waste heat is a necessary byproduct of heat engines, the efficiency of power plants and large industrial factories is limited, and they must therefore burn more fuel to achieve their desired energy output.

Once Tamir identified waste heat as perhaps the biggest piece of the climate change puzzle, he realized that “we have the potential to generate hundreds of gigawatts of zero-emission energy. But today almost no one uses it. All heat engines are very inefficient and expensive if they’re under 10 megawatts,” enough to power 300 homes.

Working with an industrial plant using any source of energy – gas, coal or solar – Luminescent’s system “can give electricity back at a very low cost.”

Tamir gives the example of the US gas pipeline that runs from the east to west coasts. “They have 25 gigawatt small turbines that operate a compressor. The efficiency is as low as 24%. We can take that 24% and turn it into 41%.”

That may not sound like a huge jump, but Tamir points out that, “just from this market in the US, we could generate the entire capacity of electrical demand in Israel, all with zero emissions.”

Gearing up for sales

Luminescent will build its first engines in Israel with partnerships outside the Middle East anticipated as the company begins signing up international customers.

Tamir is looking at a $1,500 price point per engine with the number going down as the company scales.

And while waste energy is the target, that’s just the starting point. “Waste heat that can work for decades is a big one. But renewable storage could also be an endless market. Data center cooling, geothermal energy production – these can all be endless markets,” Tamir tells ISRAEL21c.

As the Yale study noted, “Waste heat is a problem of a thousand cuts, requiring a mass of innovations to tackle different slices of the problem.”

To learn more about capturing waste heat the Israeli way, visit the Luminescent website.